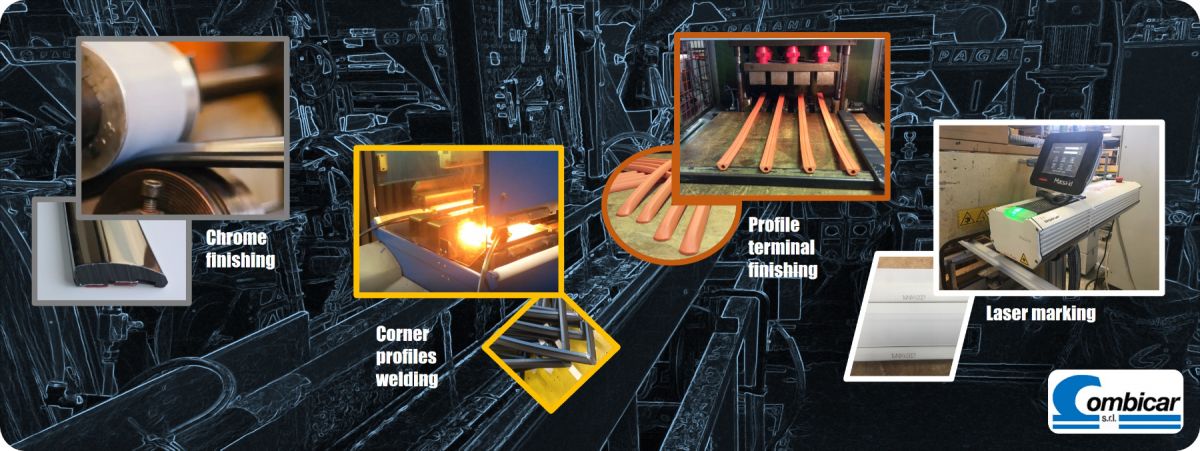

Technologies

Combicar is always looking for new technologies, internally developed or externally sourced, and for improved production methods with the objective to satisfy the market requests.

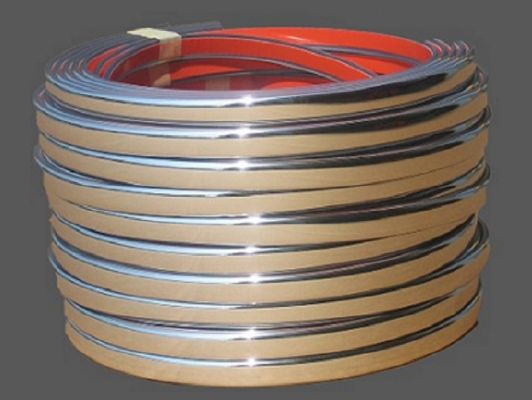

Chrome or color finishing

The chrome finishing is carried out during the extrusion phase, with the welding of a special film made by several layers of different materials that give the extruded profiles a perfect chrome finishing.

Combicar has developed a wide range of chrome finishing profiles, manufactured for many applications made in the furniture, bathroom furnishings, automotive, clothing and footwear accessories sectors.

As an alternative to the chrome effect, finishes with "metallic" effect are available, including gold, copper, satin silver, glossy black, and many others.

Finally, Combicar manufactures PVC profiles of any color from the RAL table.

Angles' welding or joining

Through the use of UV lamp welders or vertical injection presses, Combicar creates welded frames or jointed profiles also with different sections.

Thanks to these equipments and its deep experience Combicar can assure an excellent production capacity with a high quality standard, also certified by OEM supplies.

Welded frames are widely used in the automotive, household appliances and industrial refrigerators sector.

Profiles with "Ter-Melting" terminals

TER-MELTING is the special process developed by Combicar to finish the ends of some profiles.

This perfect and elegant finish allows to obtain terminals very similar to those made by injection molding.

The great advantage of this technology is a very significant reduction in the costs invested in the molds' purchase, obtaining profiles with the same aesthetic result but in different lengths.

This opportunity makes the profiles with "Ter-Melting" terminals ideal for all projects that require limited series, allowing for large dimensional flexibility and small quantities.

Combicar production technologies

This video presents some technologies and methods used by Combicar in its production of protective and decorative profiles in PVC / EPDM:

- corner welding, useful for providing the customer with profiles used as frames or welded joints

- finishing of terminals, made with the proprietary "TER MELTING" equipment and technique

- laser marking, capable of imprinting dates, production batches and other data.